Night before last, a storm blew by with a fair deal of lightning. None of it was particularly close, however. Got a few “meh” photos. Weather around hear runs through May and into June or so, at which it devolves into fairly consistent “hot and dry.” So hopefully there’ll be a few good opportunities to improve upon these results.

V3N2’s “Star Clipper” article is 26 pages and can be downloaded for $4.70.

Something screwy seems to have happened with this post. See HERE for the Paypal ordering link…

As promised, now available are the first three of a series of articles from the original print run of Aerospace Projects Review… The Werner von Braun “Ferry Rocket” article from issue V3N1, the Lockheed Star Clipper from V3N2 and the Martin Astrorocket from V3N3. These are the original articles, converted from the Word files into PDF with no compression, additions or editing. More articles like these are coming, in order of original publication. See the comments HERE to see the list of forthcoming articles.

V3N1’s “Ferry Rocket” article is ten pages, and can be downloaded for $1.80.

The very heart of science is “experimentation.” Thus, the proper scientific response to a claim that “do A and get B” is to conduct an experiment based on that claim. Does A actually cause B? Only one way way to really find out.

So some jackhole cleric in Iran claimed a few days back that women being immodest causes earthquakes. What’s the proper scientific response to that claim? Why, “Boobquake,” of course!

“I encourage other female skeptics to join me and embrace the supposed supernatural power of their breasts. Or short shorts, if that’s your preferred form of immodesty.

“With the power of our scandalous bodies combined, we should surely produce an earthquake.

“If not, I’m sure Sedighi can come up with a rational explanation for why the ground didn’t rumble.”

Science is awesome.

Here is a 44 page NASA publication in PDF form, describing the Saturn I program. This covers the basic history of rocketry up through the Saturn I, providing information and diagrams of each of the launched Saturn I vehicles, from SA-1 through SA-10.

Space Document 65 can be downloaded for the low, low price of $3.50.

Sometimes the only evidence of something truly important is a photograph of heartbreakingly bad quality. Such is the case here… two photos illustrating an experiment conducted by NASA-MSFC in 1961-62.

As mentioned before, the Saturn I booster was not initially designed to be reusable, but it was designed to be recoverable. It was expected to be damaged, but inspection of the damage would allow engineers to incrementally improve the system to eventually allow for true recovery and reusability.

There was particular interest in how the rocket engines would fare after an ocean splashdown. Rocket engines are fairly fragile… easily bent and corroded. The H-1 engines on the Saturn I were also not designed to be reusable; they were designed to be inexpensive. They were derived from the Rocketdyne S-3D that powered the Jupiter and Thor IRBM… greatly simplified (around 10% the parts count, IIRC), they also had greater thrust. But they were not designed to be used more than once.

Still, this was the early 1960’s… when the 60’s were still just the late 1950’s, before a Commie blew JFK’s brains out and set the 1960’s on the road to being the “60’s.” So, what is any self-respecting 1950’s engineer supposed to do with a rocket engine designed to be used once and then thrown away? Why, test fire it, dump it into a tank full of corrosion, have the janitor swamp it out, and fire it again. So they did just that. And what did they find?

The H-1 engine was perfectly capable of being re-used, and at extremely low cost.

The two photos I have of the experiments are below. Yes, they suck. But they get across the idea magnificently. Imagine the paperwork and endless series of meetings with customers, management, Unions stewards, bean counters, environmental cops, hell, the friggen’ diversity co-ordinator that would be required to do this sort of experiment today with an engine like the SSME that actually *was* designed to be reusable.

Granted, the H-1 was not designed to be as efficient as the SSME. It did not operate at the extremely high pressure that the SSME does. A fully reusable launch vehicle based on the H-1 would be a crude affair… probably a two-stage vehicle, as getting SSTO performance would be a challenge. But still… who cares? If you can make your rocket for dirt cheap, and operate it for dirt cheap… then your pitiful payload fraction still looks damned wonderful, as your cost per pound is far less.

NASA has, over the last 45 years or so, decided that the way to make space travel cheap is by focussing on the most expensive bleeding edge technologies. Had NASA, instead, focussed not on micromanaging the technologies used in the launchers, but instead on simply *getting* *there,* then I think it’s safe to say that by now the spacelanes would be filled with tourists going to GEO hotels on the rough equivalent of VW microbuses.

A description of the tests:

H-1 ENGINE SALT WATER IMMERSION PROGRAM

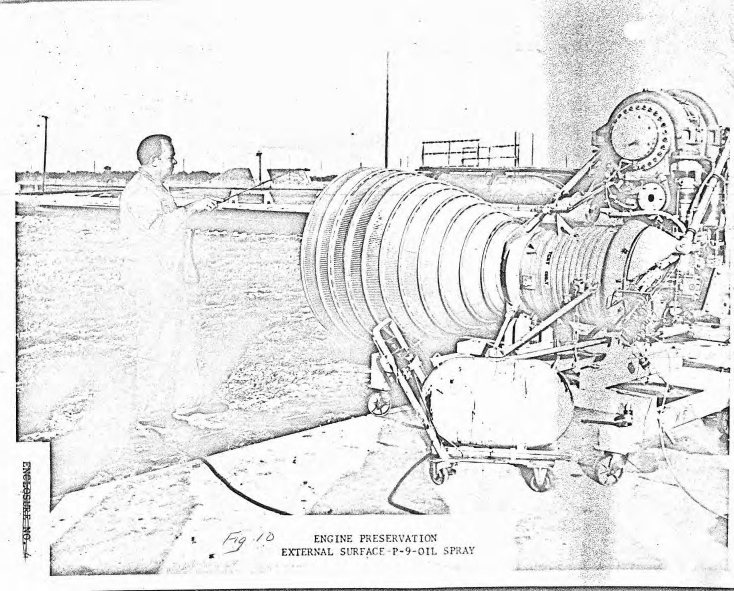

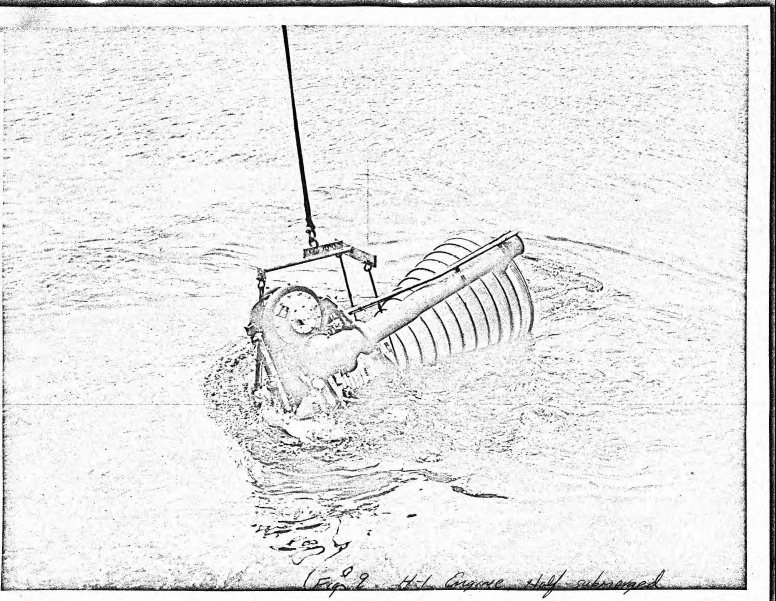

Sea water immersion tests were conducted on a Rocketdyne H-1 engine in order to evaluate the corrosive effects of sea-water recovery on the engine and to define the procedures necessary to restore the engine for flight service, The H-1 engine is the one presently used, in a cluster of eight, to power the SATURN C-1, S-I stage. The water immersion program involved a series of tests in which the H-1 engine was immersed in sea water for given periods of time, followed by various post treatments designed to minimize the corrosive effect of sea water. The engine was then disassembled, evaluated for corrosion damage, reassembled, and test fired (figures 9 and 10).Figure 9. H – 1 Engine, Half -Submerged.

Figure 10. Spraying H- 1 Engine after Recovery.

The purpose of this test program was to better define the effects of salt water immersion on the H-1 engine. Because of the various recovery schemes proposed for SATURN booster recovery, it was essential that hardware such as an H-1 engine be immersed in salt water and the results investigated to better evaluate the economics of booster recovery (wet versus dry recovery systems). The salt water immersion tests, reconditioning, and subsequent full duration static firings of the H-1 engine provided valuable information reflecting the feasibility of re-using large boosters after exposure to salt water.The test program scheduled a series of three immersion tests with subsequent hot firing in the test stand. The first test was performed with known preservative measures, the second with less preservation, and the third and final test with no preservation methods applied. The salt water immersion was performed at Port Canaveral, Florida, and the dismantling, checking of components, assembly, and hot firing at the MSFC, Huntsville, Alabama.

The general test procedures were as follows:

1. First test – March, 1961. H-1 engine was:

a. Prepared and static fired.

b. Immersed in salt water to a depth of 10 feet for 2 hours, and half -submerged for 2 hours.

c. Purged. Preservations were applied.

d. Stored for 2 weeks.

e. Dismantled, inspected, cleaned, damaged parts were replaced, and engine was assembled.

f. Hot fired for short duration and full duration (150 seconds).2. Second test – June, 1961:

a. Immersed H-1 engine to a depth of 10 feet for 1 hour, half submerged for 3 hours, and on the surface for 3 hours.

b. Waited 12 hours before purging, and applying minimum

preservatives.

c. Upon arrival at the MSFC, engine was dismantled, inspected, cleaned, damaged parts were replaced, and engine was assembled

d. Hot-fired for short duration and full duration.3. Third test immersion in August, 1961; hot fired in March, 1962.

a. Dropped H-1 engine into water to simulate water entry conditions, immersed it, held it half-submerged, and on the surface for a total of 9 hours.

b, Engine washed with fresh water; – no preservative compounds were used.

c. Upop arrival at the MSFC, engine was dismantled, inspected, partially cleaned, ind left in storage.

d. Six months later the engine was assembled and hot-fired for short duration and full duration.In order to establish an approximate cost factor, a log was kept of the procedures, reconditioning manhours, materials, and an itemized list of replaced engine parts. The cost to recover and recondition the H- 1 engine was approximately 5 per cent of the cost of a new one.