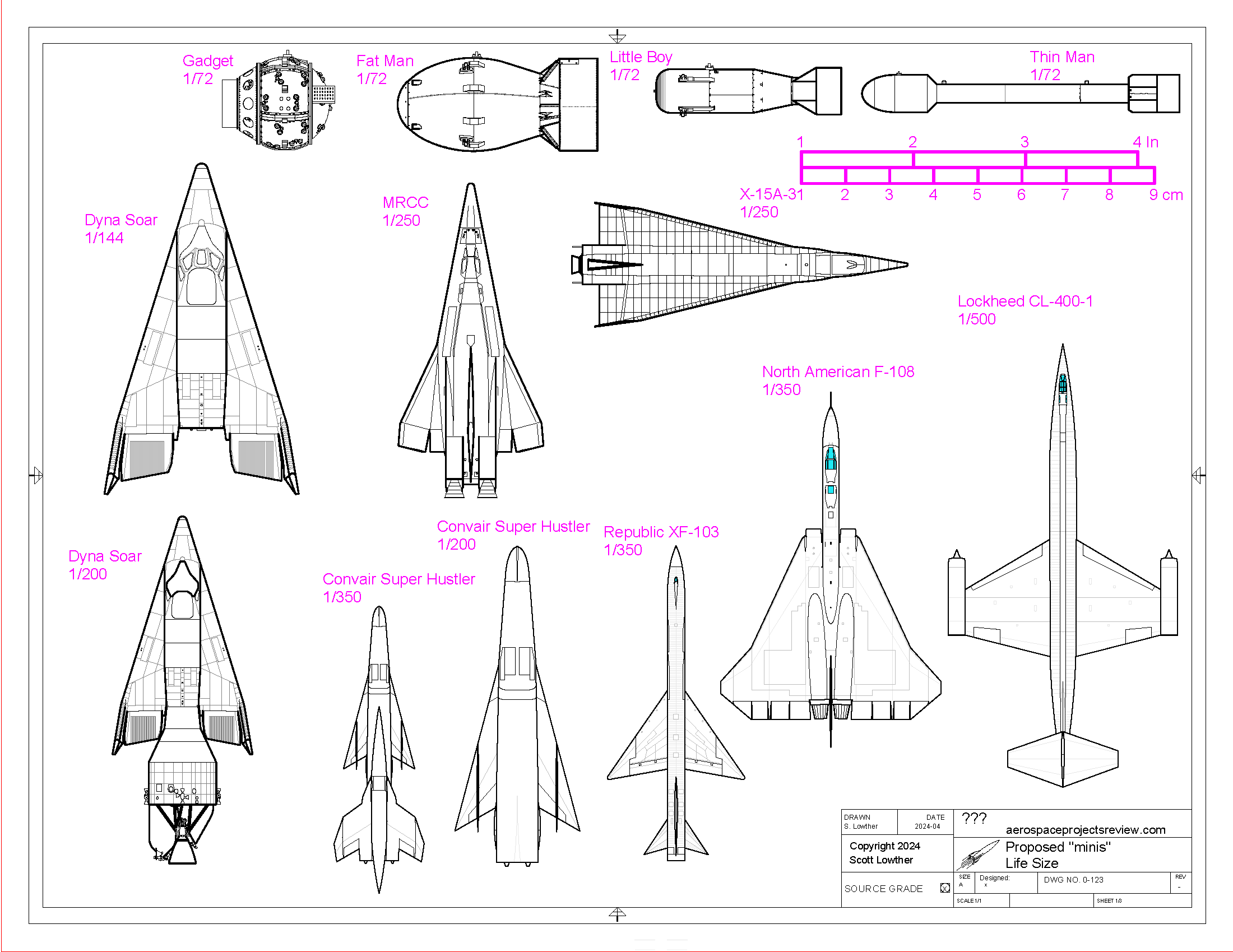

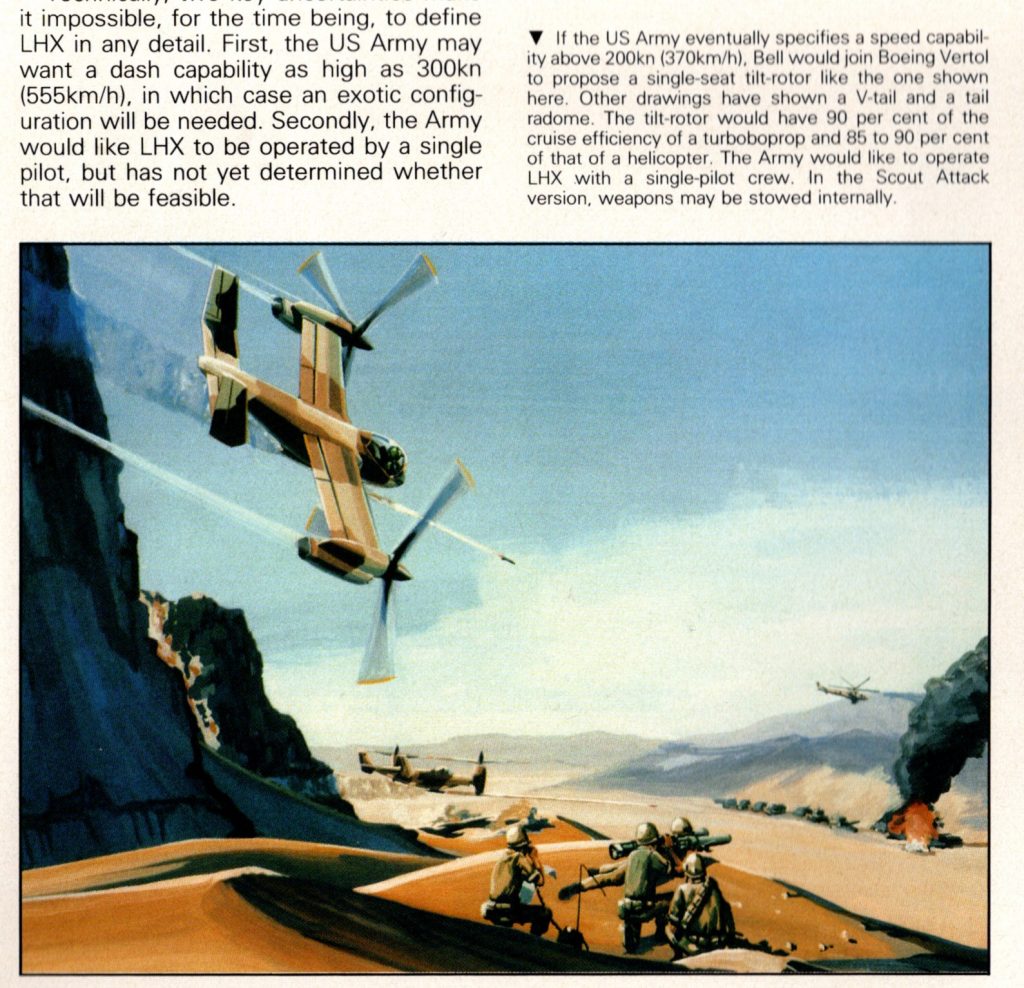

I’ve printed off two more Fat Man bombs in 1/18. I can see where improvements can be made to the CAD model, but as is they’ll build up into spiffy little pieces.

Right now I’ve got 2 Fat Man, 2 Little Boy hopefully to sell to help defray costs; if there is interest I can clearly print out more. If interested, let me know. I have two of each right now hopefully to sell to help defray costs; if there is interest I can clearly print out more. So… who wants ’em? $60 per Little Boy, $100 per Fat Man, plus postage. If you want both Little Boy and Fat Man… $150 + postage.

If I refine these for a regular production run, there will be some changes for improved printing, some additional details and importantly stands. But “if” is doing a lot of heavy lifting, and the refined production kits will probably run 1.5 to 2 times as much. 3D printed kits provide options that cast resin kits can’t match, such as complete tail units, but they take many hours each to produce.

![]()

Photos at Twitter:

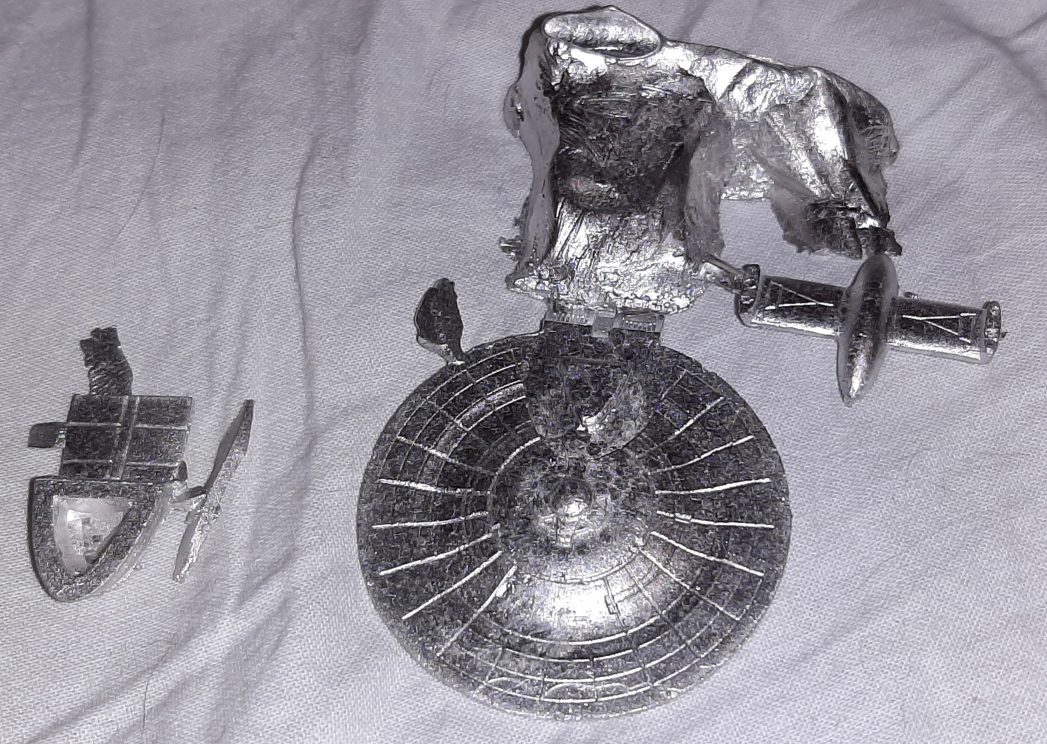

The two new 1/18 Fat Man units. I can see where improvements can be made to the CAD model, but as is they'll build up into spiffy little pieces. So… who wants 'em? I've got 2 FM, 2 Little Boy. $60 per LB, $100 per FM, plus postage. If interested, let me know. pic.twitter.com/POjyRAyDLF

— Unwanted Blog (@UnwantedBlog) April 30, 2024

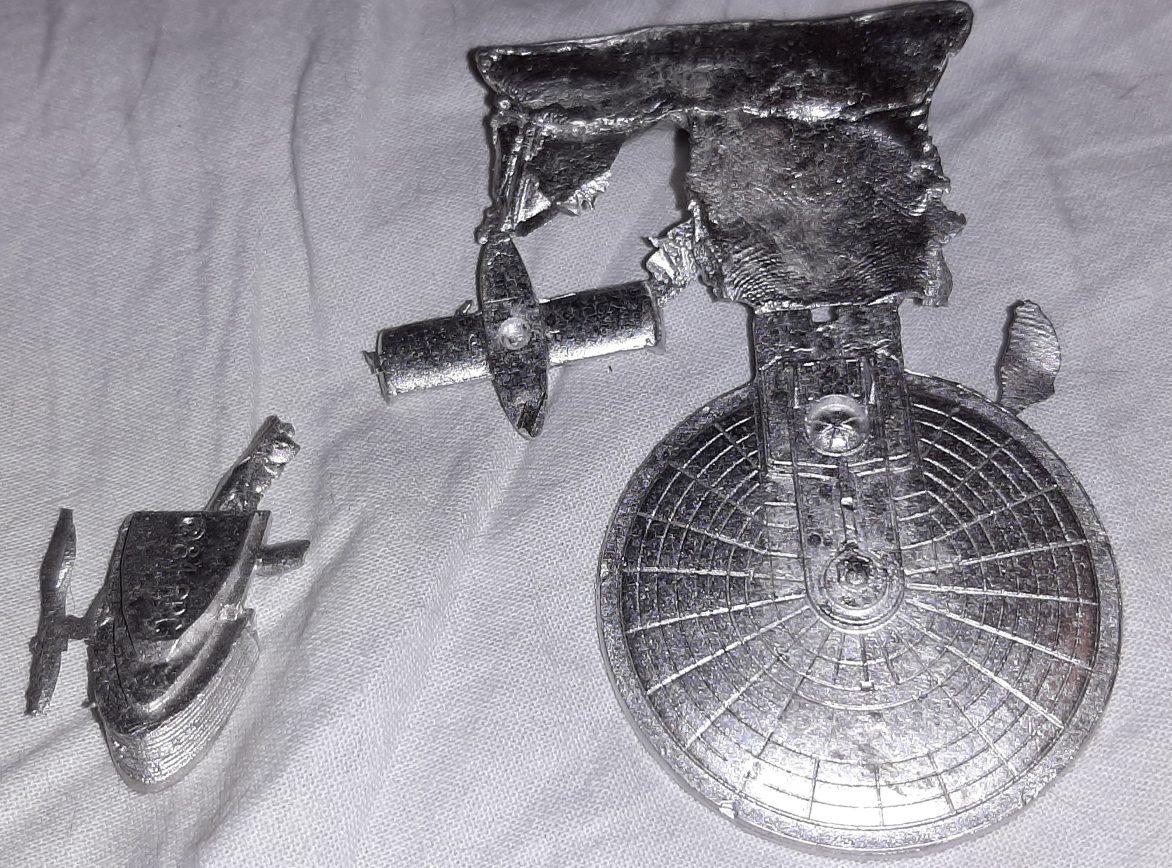

1/ Second version of the 1/18 Little Boy. Two fit on the printer at once; both came through with flying colors. the thickened tail surfaces worked like a charm; doesn't seem too out of scale. Flash seems to exaggerate surface imperfections. pic.twitter.com/m8nWg1TdAY

— Unwanted Blog (@UnwantedBlog) April 28, 2024