I recently downloaded a presentation from Hoppy Price of JPL and Alisa Hawkins/Torrey Radcliffe of the Aerospace Corporation describing “Austere Human Missions to Mars” (available as a PDF file HERE). Regardless of the other merits of the presentation, the illustrations… well… the illustrations made my tiny little brain cry.

Back in the 1950’s and 1960’s – you know, when there was actual progress in aerospace – aerospace companies and organizations had people on staff who were paid, skilled artists and draftsmen. Many of even the simplest presentations were thus filled with high-quality sketches, drawings, artwork, photos of scale models, etc. But in recent years, certainly since before my aerospace career began in the mid 90’s, there has been a consolidation of skills into a smaller and smaller group of people. I often heard tales of how the floor of the office was ringed with engineers on the outside, filled with draftsmen in the middle, and had secretaries/technical writers on the ends. The engineers would crunch the numbers, the draftsmen would make the drawings, the secretaries and writers would write up the reports (often using little more than random scribbles and scraps scrawled by the engineers). The system may have been unweildy and inefficient, but obviously it worked.

But with the rise of the personal computer, word processing programs and CAD programs, the apparent “need” for the non-engineers declined. Why have a draftsman when the engineer can do the drafting himself? Who needs a secretary when the engineer can do the writing himself?

Well, a few seconds of thought can show why the New Order Of Things might not be optimum. Basically, you’re taking specialists (engineers) who would normally spend 8 hours out of an 8 hour day brainifying engineering, and converting them into generalists who spend a much-reduced fraction of their day doing what they were trained to do. Worse, on the whole trained draftsmen are betters at drafting than engineers; good secretaries and technical writers are better and faster at writing than engineers. Thus, not only do the engineers spend less of their time doing engineering, the time spent doing Other Stuff is much less efficient than if that Other Stuff was done by Other Stuff specialists.

Compounding the problem is Powerpoint. Used to be, when you needed to make a presentation (typically based on transparencies for an overhead progrector, or even – GASP – slides) , you had your tech writers and draftsmen/artists on staff doing their thing. But then Powerpoint came along. Presentations were now easy to make. Powerpoint even came with an ultra-basic graphics package allowing anybody – no matter how artistically unskilled – to slap together illustrations that at least vaguely resembled whatever it was they were talking about. And so now that engineers could do the whole thing from beginning to end, it was just sorta assumed that they should do the whole thing from beginning to end. Great, fine, whatever. But as desirable as it may be for engineers to also be good artists… most aren’t. Powerpoint is a fantastic way to present text, data, charts and the like, and makes a perfectly good platform for the presentation of art and diagrams created via other means, but Powerpoint-created art is, well, lame.

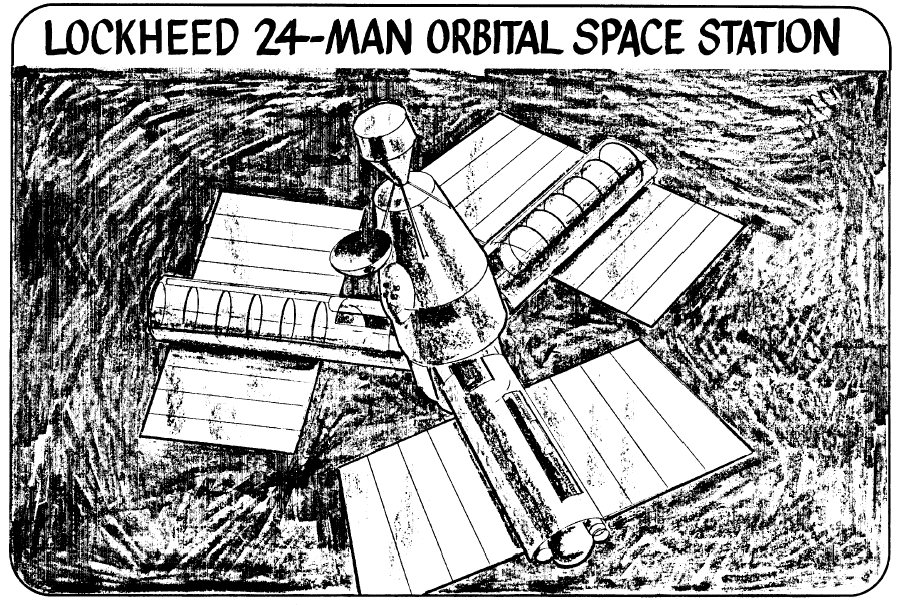

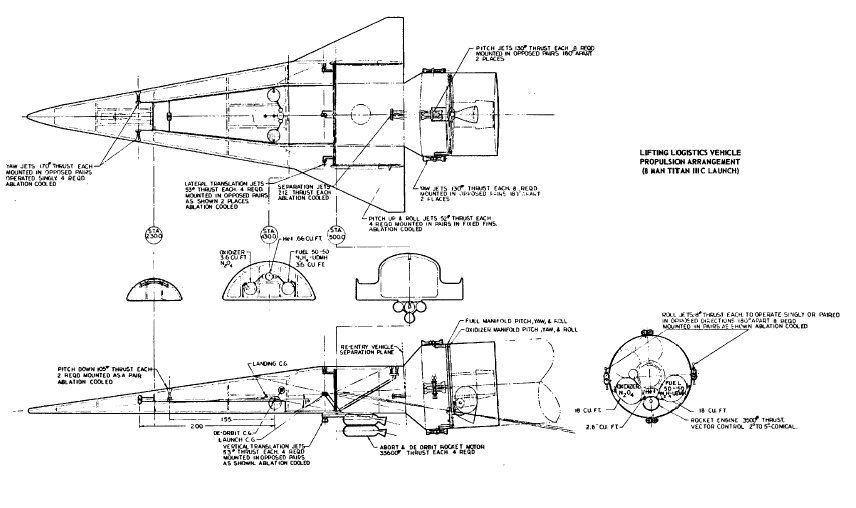

Compare and contrast. Here are two illustrations from the “HYLEAP Management Progress Report, June-July 1964,” (which anyone interested can procure HERE):

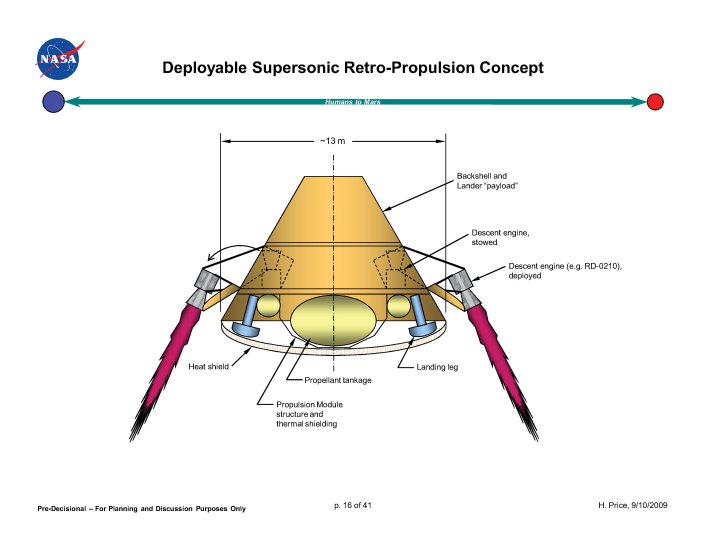

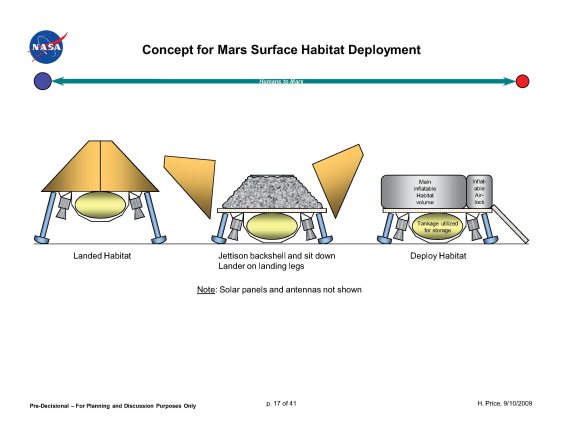

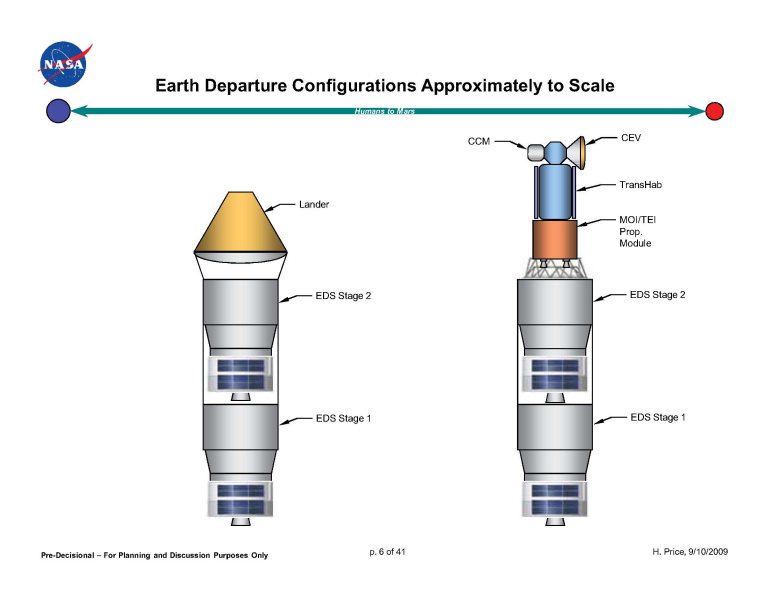

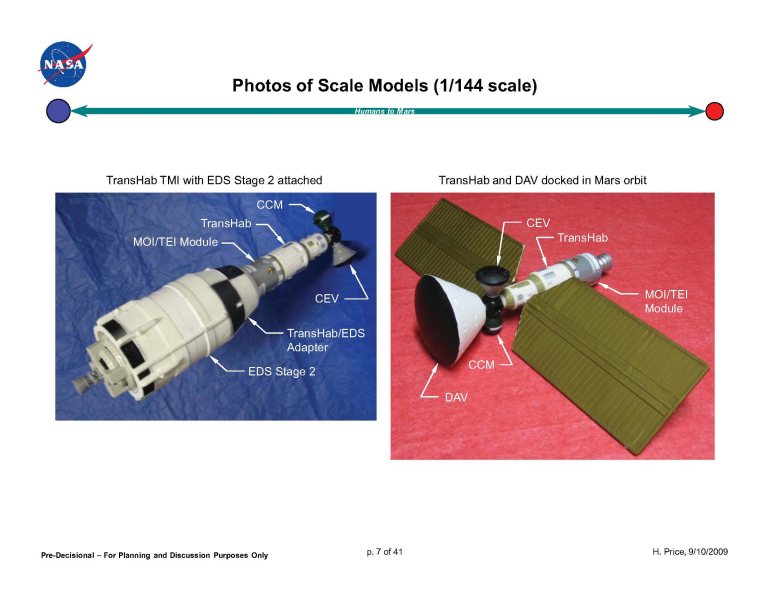

And here are the Powerpoint illustrations from the recent Austere Human Missions to Mars presentation:

Note that the last illustration shows models of the Mars vehicles, apparently put together from toys.

Oy.

In comparison, previous eras, when aerospace companies regularly employed model makers, saw stuff like this:

And yes, some companies still employ model makers, but it seems to be a dying part of the industry. United Technologies near San Jose, CA, used to have a dedicated model shop, and cranked out a wide variety of models to illustrate both built and unbuilt designs. But by the time I started working there in 2000, the model shop and all the model makers were a distant memory. When I worked at ATK, there was a grand total of one model maker, who was also the one painter/illustrator on staff. At both companies, most of the presentations I saw were horribly, horribly awful in terms of graphics. Now, I’m not saying that there’s a direct link between presentation graphics and company survival, but United Tech is now a bulldozed memory, and ATK, at least the Promontory facility, is laying people off and will probably lose the largest program there. Soon enough it will be a hobbyshop for rocketry.

The worst of it was, while at United Tech, a number of NASA engineers came for a meeting on the Shuttle RSRM Booster Separation Motor… and they used Powerpoint to calculate areas in a part by projecting clip art onto a wall and measuring dimensions with a ruler. I had to leave the room.

24 Responses to “Powerpoint engineering and the downfall of quality”

Sorry, the comment form is closed at this time.

Puke on Powerpoint.

i wand the good old time BACK

i wand model makers/painter/illustrator

that i’m illustrator play here only a insignificant role…

That last is SCARY. I have essentially gotten out of new construction because of the low grade, absolute HORRIBLITY of prints churned out by “architects” anymore. I can bloody well do better with a legal pad, ruler and pencil, and on remodel, porches/decks, patios(brick,flagstone,cement pads), and landscaping jobs I routinely do.

Technology is generating a backlash. I see in a lot of different people, they are rejecting much of new tech, many because it just won’t stop. Come up with a good, workable system of some sort and it is ditched for some new in the twinkling of an eye.

I hint to the IT industry. ENOUGH ALREADY!!!!!! We don’t need a new “latest thing” every damned day. Give. It. A. Rest.

My first real job out of high school was with a bunch of electrical engineers at a power company. We had a room full of commercial artists and draftsmen who created drawings of everything. It kept the engineers doing their job and not being distracted. Twenty years later, when I was laid off from that company, engineers were doing the drafting and the useful drawings we had were gone. Engineers weren’t really engineers any more because they were doing so much clerical and other stuff. While I wa a project manager there, I’d add to the team an accounting person (usually a woman), and the engineers never had to worry about that kind of trivial, either.

The IT industry turns out new stuff because that’s all they have to do. I’d have been happy with WordPerfect 8, but without a new product the software company vanishes.

The 20somethings who are doing the drawings are inordinately proud of “taming: the graphic software. They should be proud of doing a good job and presenting an idea clearly and concisely — but they are not: they seem to focus on making a show.

I’m not sure exactly what’s going on, but part of it is that no one really has the freedom to create anything new and significant. Some part of it also is that they have been trained to regard the old ways as inferior.

I gotta think about this.

I was a Drafting major in 1997 bfore I joined the Navy. My school still had honest-to-gods pencil and paper drafting.

When I got back to school last year, it was all AUTOCAD.

The kids I go to school with couldn’t do a paper diagram if their life depended on it.

As for the model issue, it’s sad that the engineers chose to cannibalize a good Saturn V replica like that. They couldnt just make their own. Lame.

All of it. Just

just lame

A couple of things are going on.

(1) The perfection of digital graphics are seductive, regardless of whether they’re accurate or edifying.

(2). I’m old enough to have worked on publications before and after computers. Before: “You’ve got a month to do this pamphlet.” “Can I do an illustration?” “How long will that take?” “Another week.” “OK.”

After: “You’ve got a day to do this pamphlet.” “Can I do an illustration?” “Are you crazy? Use some clip art.”

So, by this metric, I’m many times more productive. Confusingly, I’m not any richer.

Very interesting. There’s been a lot lost in the past 30 years. Many of today’s engineers have no idea what is involved in producing an engineering documentation package.

This includes basic engineering drawings, bill of materials and in particular dimensioning and tolerancing. And I’m talking basics let alone GD&T.

It’s very common to see companies using mechanical engineers equipped with 3D CAD programs (i.e. SolidWorks, Pro-E) to create models and products. But when it comes to basic design and drafting skills there’s a huge void.

Great blog – you’ve hit the nail on the head re. the source of “Death by PowerPoint”. Allow engineers to engineer…and let graphic designers/model makers and the like do what they do best.

Just because the PowerPoint icon is on your desktop does not mean you have to use it!

I submit that the final CAD model of an item can be rendered into a pretty compelling image, but I agree that the preliminary illustrations and models have gone downhill a long ways.

Jim

This extends all the way into every school in the US. Kids these days are taught to use the Internet, MS Word and MS PowerPoint for literally everything. What comes out of this? Really crappy “papers” and “presentations” which are 99% cut and paste. Kids these days spend far more time worrying about fonts for their “papers” and fancy PowerPoint effects for their “presentations” than they do about the substance of their presentation.

The bottom line is that the next generation of engineers won’t even be capable of writing a comprehensible paper, but the fonts will be pretty. Their presentations will be full of audio and video effects, but almost completely devoid of original thought.

As a manager of technical writers and usability engineers, I can state unequivocally that dropping the specialists (modelers, writers, illustrators) is a false economy, and I have the empirical data to back it up. Sadly, the typical company’s cost accounting model treats these roles as overhead and can’t always quantify the payback.

However, I just finished up a project in which the VP refused to pay for a contract writer for 6 months. So, he had senior engineers write up user documentation and submit it to my team for “editing”. He probably invested three man-months of his team’s time in this, all told, with big-company loaded costs as well. How this is saving the company money is beyond me, but again, the system counts contractors as expenses and Q4 is a bad time to ask for money for expenses.

Meanwhile, the user doc was written in a different style and made life difficult for our localization people. Yet localization is done in another silo, so we officially didn’t care. But I’m told we’re not “embracing change” when I point this out to people.

That’s one of the reason’s I want to do the Aerospace Design Museum, to preserve the Art and Design of the aerospace industry and create a narrative about how things are concieved, developed and sold to the buyer.

I run my own model-making business, everything from getting the contract to shipping and setting up the models. One thing I know is true is that model makers make lousy business people. I hated keeping books and filling out government forms so I hired a secretary for that.

For most of the building I was able to use CAD/RP processes and I usually had an apprentice for teaching them the Power of the Dark Side of the Force!!! errr… not getting resin in your eyes.

Computers are just another tool like a paint brush, typewriter or sliderule, just faster and on one tool. It seems like that’s a good way to make a person with one good skill and making them into a jack-of-all-trades.

Right now the emphasis on school training is on how to operate the tool and not enough time on what good design is and how to tell the difference between good and bad.

The Methodology used by the WW2.0 gen and baby boomer engineers didn’t get passed along due to the downsizing of aerospace and the lack of computing power to turn paper docs into an electronic format so much of that knowledge was thrown away.

The technological gap between the current gen and the older ones might make it difficult to pass on the memories of how they built something that got to the Moon using slide rules. It’s hard to clearly remember how i built some of my early models, and that was only 20 years ago, think about remembering 40 years ago and the only way to share that knowledge quickly would be using a computer and the internet.

Lots of good comments!!! Booyaa!

I did not have such a low opinion of architects and engineers until the late ’90s into 2000. We began getting prints for houses, duplexes, garages and whatnot that were F***king gibberish. Had to sit down and reconcile all kinds of crap before you could use then, and sending them back for corrections was an exercise in futility. And yes, I understand that customer changes are part of it, not nearly all of it. I can talk to the bloody customer and make changes.

In the spirit of full disclosure, I am a high school drop out, got my GED after basic training US Army, served as Field Artillery crewman and Forward Observer. Got several months in college level courses from OU Norman through Army, meteorology data collection and interp.(can’t be popping tactical nukes if you don’t understand wind patterning and basic weather effects) And have spent most of my life in carpentry, construction, remodeling.

It’s gone downhill since the 90’s.

My third day in class last year, the instructor had us do simple block diagrams. The kids in my class started to do it on computer. The look of confusion on their face when told we had to do it on paper was priceless.

You’d think the teacher had asked them to stand on their heads. They hadn’t even though to bring graph paper with them.

I kinda had a hunch the teach wanted to see what we could do on paper.

That, and I had already taken the original paper Drafting course back in the mid 90’s.

The times they are a changin’. And not for the best.

And when my school doesn’t even carry a simple French curve in the bookstore anymore and I have to go on an off-campus quest for one, that’s when I know it’s all going downhill.

On the topic of CAD vs hand-drafting… well, I certainly like the look of handmade diagrams more than CAD, but the end results are essentially the same (with CAD definitely winning in terms of accuracy, precision, clarity and changability). Similarly, handmade models and CAD-built and stereolithograhically grown or NC milled models wind up being the same things. Having gotten to Illinois state level drafting competitions back in my high school days, using the old T-square and such… I can’t say as I miss it that much, and don’t see the transition from pencil to mouse as being troubling.

What *does* trouble me is the ready acceptance of crappy illustrations, no matter how made. And computers do make it easier to slap together utter crap. Before computers, the illustration would have been done by someone with some actual artistic skill… or not done at all. Powerpoint and it’s minimalist graphics capability seems to lead people to think that *anyone* can create diagrams that are “good enough.”

What are those aircraft on the deck of the USS Ranger CVA-61? Especially the ones that resemble the Convair NX-2.

Admin response: Those are somewhat ill-defined nuclear powered aircraft, clearly based on the NX-2, but much reduced in size. Comes from a Convair presentation about nuclear powered aircraft for carrier duty… the mini-NX-2, a nuke VTOL AWACs, a Pluto-like missile.

At a local craft shop last night I bought an architect’s rule — the three-sided thing. There was an end cap (about 6×4 feet) of the stuff for hand drafting. Even an erasing shield (about half the thickness of the one I have). Also several sets of French curves, two sizes of T-squares, and several flat rules. I’d never seen that stuff at that store before, and I don’t recall seeing any of it recently. (I bought the architect’s rule for my son. )

A type of art no one has mentioned is the patent drawings. Now, they’re uninspiring CAD things, most of which look they’ve been stretched to twice normal size to fit onto the page. I miss the careful renderings of things like the B-26’s glass nose (Patent 2,372,939) and Battey’s Aerial Machine flying over a New York valley (Patent 502, 168).

I gollect old drafting instruments and especially ships curves. At Art Center the first thing you make is a set of Toyota curves, large ships curves that are perfectly accelerated. If you wonder why all cars look the same, it’s due to the fact that most came from Art Center and were taught the same thing by the same teachers. It sounds bad but it works very well.

Unless you’re very good at CAD, sketching is very difficult, but with markers for drawing and clay for modelling, the little things that are unintentionally created lead to even better designs and with your hands on the model, you can feel the surface.

I was lucky to have learned old school drafting and enough new CAD to put me ahead of the competition, even now a little.

It’s too bad America relies so heavily on little silicon chips that can be wiped out by EMP’s. That’s worse than any natural disaster. The big problems wouldn’t be fallout or chem bio nuke, it’d be your neighbor you’ve never met who just used the last bit of water in his toity and now he wants yours.

I wish I could find a school that’d teach my son how to fish, grow things, build things, kind of like Boy Scouts and Girl Scouts combined. Then the kids could tell the adults how to survive. When you’re young, things like that are fun, at least they were for me growing up in the country.

I really like the PhanTomcat concept model! That would be any easy build. Do you have anymore info on that? Even the base looks cool.

This will make ya cry (A brief exerpt from “From Rainbow to Gusto”)

“The next day Baldwin began designing the “tug” aircraft to tow the reconnaissance vehicle to altitude. It had to tow a 25,000lb aircraft with a L/D of 10 (he apparently felta higher L/D was justified) to 70,000 ft ata Mach number of 0.8. Three days later he completed the three-view drawing.

Today it would take a team of engineers a year just to decide on a layout. One dude, three days.

As someone working in the aerospace industry I can’t tell you all the “you gotta be shitting me” moments I’ve seen. You could probably throw a coil around Kelly Johnson’s grave and solve the whole energy problem.

I second that notion.

[…] case, I was put in contact with one of the artists employed by General Atomic Back In The Day (see HERE for more discussion of the long-lost Time Of Quality Aerospace Artwork), and it happens that he illustrated the landing boat. Sadly, the art seems to have been stuffed […]

A born drafter, 17 years on the board, started with 3D CAD on CV in 1982, PC based CAD VAR from 1986 until today. The drafter was the Keeper of the Sacred Standards. Today we watch as IT folks and engineers (who never release a design package in their lives) re-engineer engineering based on the Major CAD systems. PLM/MBE are systems destine to fail. No Standards.

Been around a long time, started “Engineering” when my grandfather sat me in front of 2 lawn mowers and said the hand mower works fine but the power mower needs work “hand or power it’s your choice” looking out over 3 acres of lawn I learned problem solving, When I was finished I made sure it ran flawlessly and looked as good as a 20 year old mower could. My grandfather came by and said “Look’s good” no trophies, stickers, pat’s on the back. That’s how you develop pride in workmanship, After mowing the lawn I had a list of ‘Improvements & changes’ that’s design review. I went on to college & the Merchant Marine that’s developing the necessary skills. Then I actually learned my craft from a 30 yr engineering vet both on the board & with CAD & 3D. Then I was a passable engineer. Today it’s, ‘pass the test’ 4 yrs ago I couldn’t spell engineer now I are one. Looking good has become a substitute for craftsmanship, pride in workmanship is something the ‘Old Guys” are always going on about, what design review, my design’s perfect just look at it. There’s no interest in developing the skills to become competent. I actually had to point out to a junior engineer that his design ‘might’ work, but we could never sell it because it would cost 3x what our competitors are selling them for, his response was ‘So your not even going to try it?’ If he had even bothered to do a basic BS check on the design he would have pulled at least a dozen mistakes. But it was a ‘New / Cool Concept”.

I agree Engineers including myself make terrible secretaries, draftsman, file clerks, accountants, authors, and whatever else we’re asked to do that’s not engineering. Why would a company pay an engineer’s salary to have him shredding papers 30 minutes a day, or maintaining files. I think companies need to do a more detailed analysis of their costs and take Engineers out of “Overhead” to see what this change is truly costing them. If I hear ” They’re sunk cost on overhead, we’ve already paid the bill for them” one more time I might have to grab my T square & beat a bean counter to death.