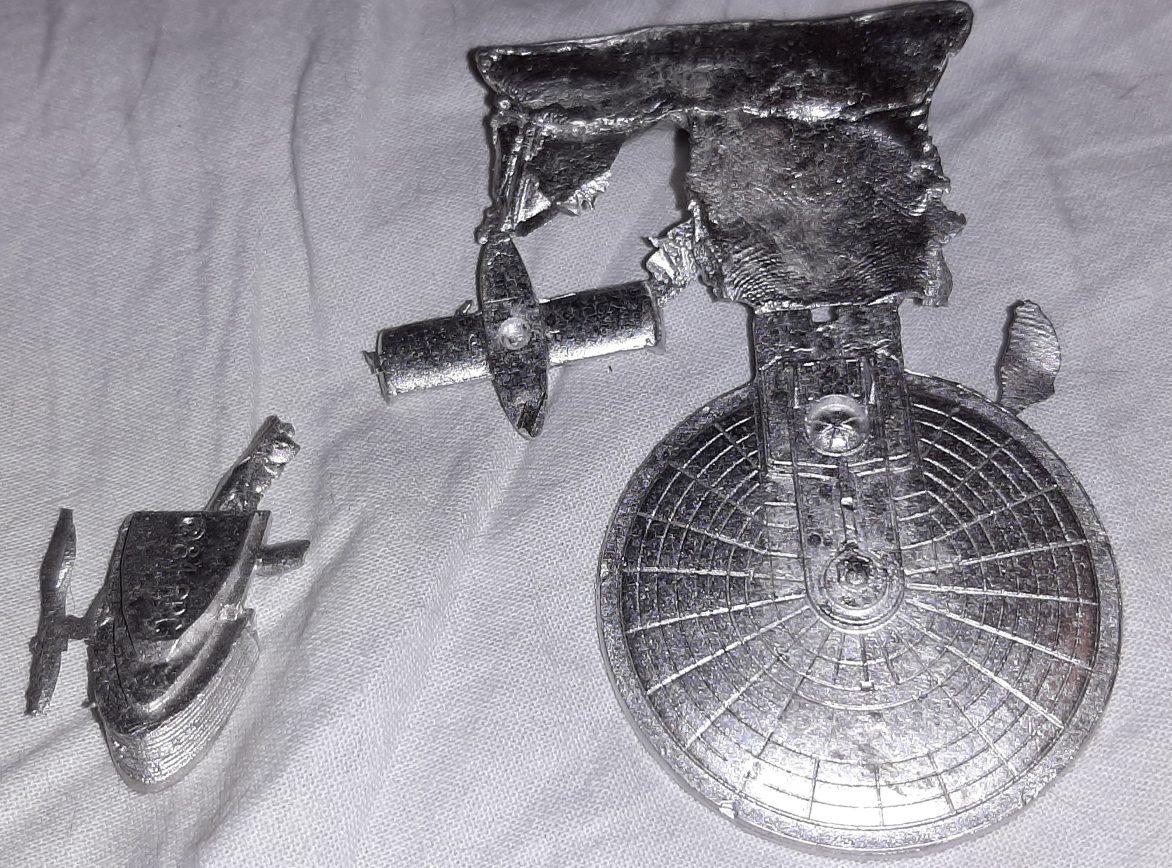

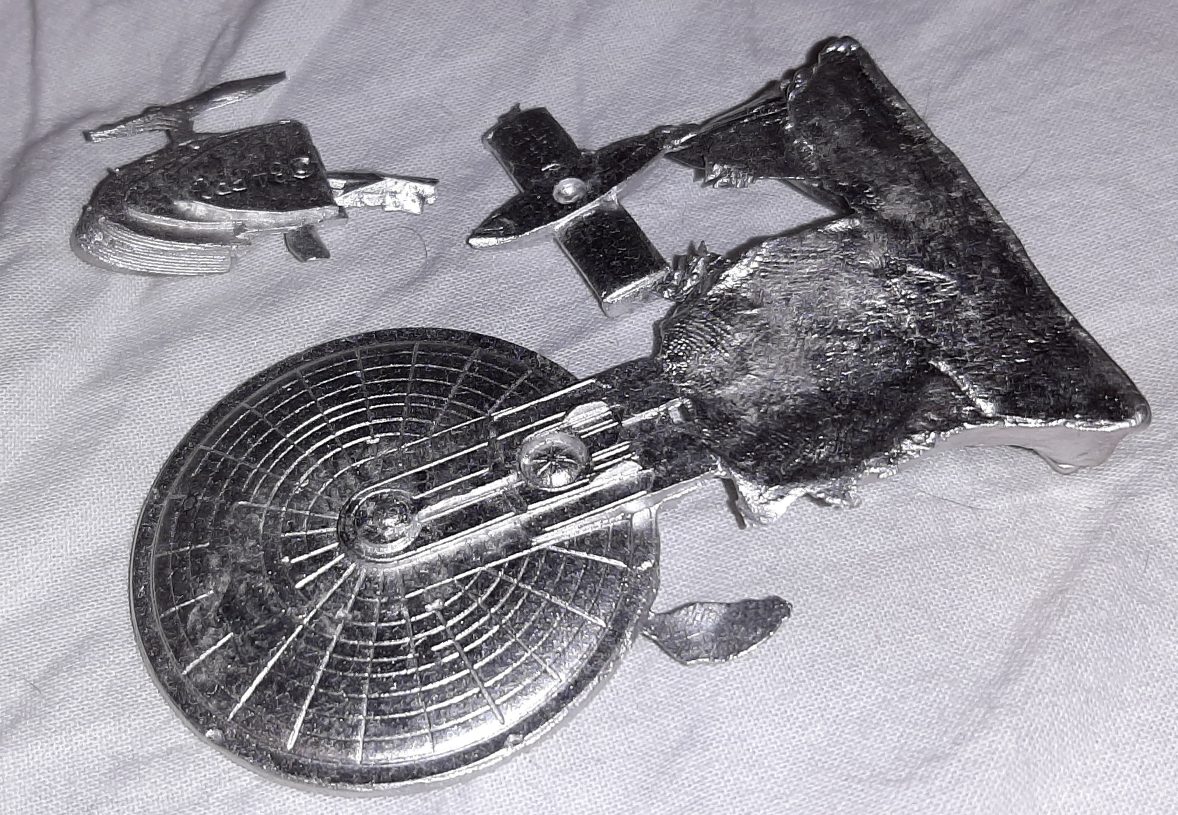

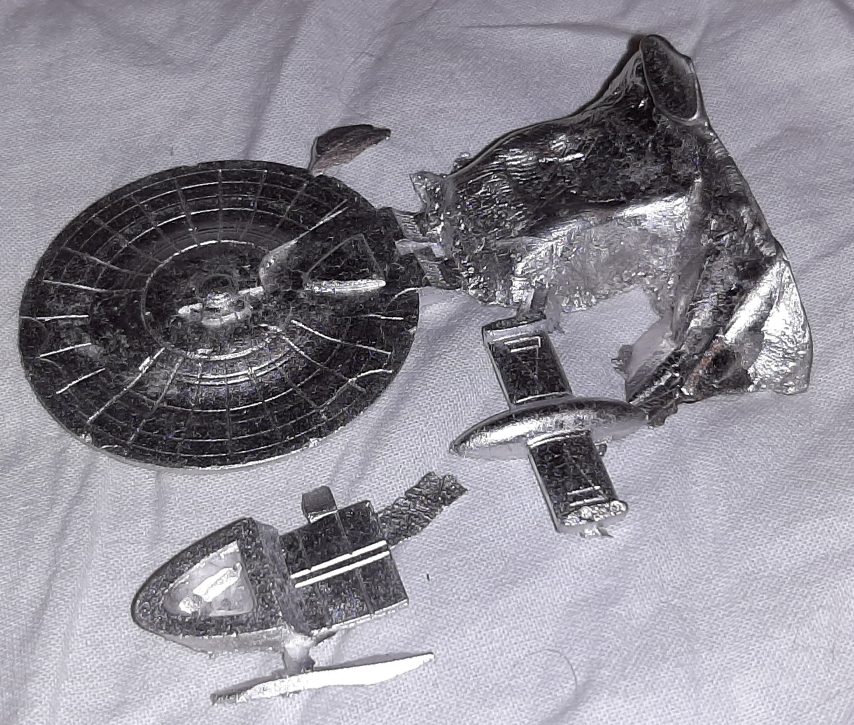

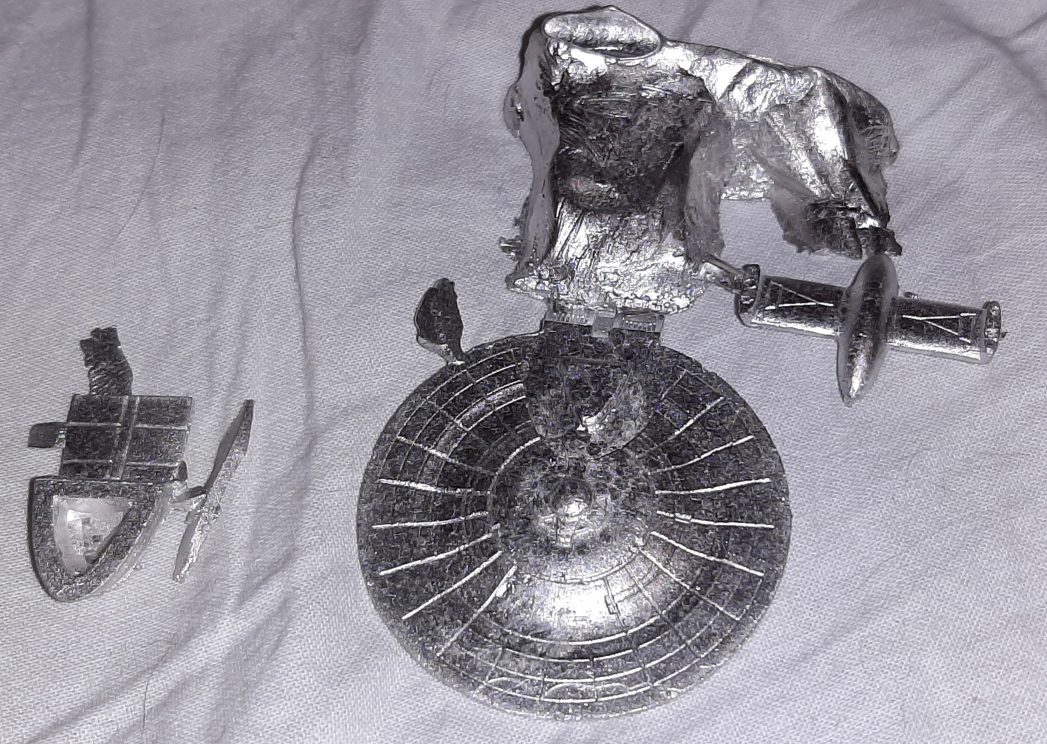

Some thirty or so years ago I took a stab at casting small parts and models in metal… my very early 1/144 lifting bodies, X-20, etc. The results were sad, so the project was abandoned. For reasons that evade me I’ve recently decided to try again. Materials available to me today are much better… high temp silicone, low-melt temp no-lead alloys, a cheap electric melting pot (rather than a massive cast iron ladle and a blow torch), and I’m slightly more skilled, slightly less stupid. Still, it’s disconcerting when it works right out of the gate:

For those not old enough and nerdy enough to recognize, these are parts from the mid-80’s FASA NX-2000 Excelsior miniature. The flash seems to pick up the crystalline structure in the surface much more prominently than they appear in reality, and there is clearly a flaw with the mold on the underside of the saucer. But otherwise they came though not only with no flash but also fully filled, no bubbles. I’m quite pleased and more than a little baffled. Immediate success is unexpected.

What to do from here? I’m not going to recast the FASA ships; this was just a test. However, I might take a stab at some *different* ships (NCC-2000, NCC-1701-B are obvious choices). But mostly I have an unaccountable urge to cast entirely new minis. I don’t think there’d be a market, but *I* want them… gaming scale Orion nuclear pulse vehicles, Dyna Soars, F-108s, etc. are the sort of things I’d have blown my allowance on back in the 80’s.

Next up… gotta acquire a good 3D printer.