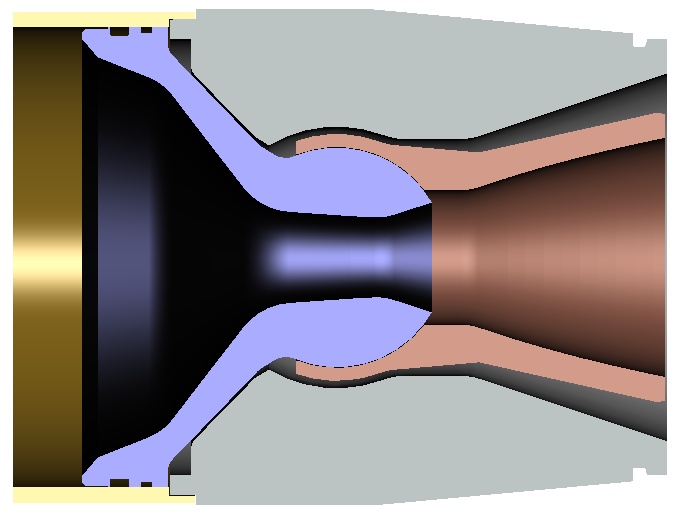

This here is what you call a “supersonic split line nozzle.” It’s not commonly encountered out in the wild, but it has been tested for decades for use as a vectorable nozzle on relatively small solid rocket motors, generally military missiles. The ball-and-socket design allows the nozzle to be gimballed (either hydraulically or electromechanically); the unusual location of the splitline (where the fixed part meets the movable part) downstream of the throat means that the joint is moved out of the high-pressure environment within the motor. A nozzle like this *should* have lower leakage and erosion issues that a subsonic splitline nozzle, while being easier to move than a nozzle with a flexible joint (basically a rubber gasket that is bonded to both sides and requires a whole lot of force to horse around) with easier thermal issues.

May 222016