I think I’m pretty good at 2D drafting and at 3D CAD modeling for 3D printing and such. But I’ve very little experience with texture mapping and rendering for “art.” But while modeling the JPL interstellar precursor spacecraft for the next issue of USSP, it occurred to me that the model didn’t look half bad just with basic coloring of the parts. While this may work for spacecraft, I don’t imagine it’d be all that wonderful for aircraft.

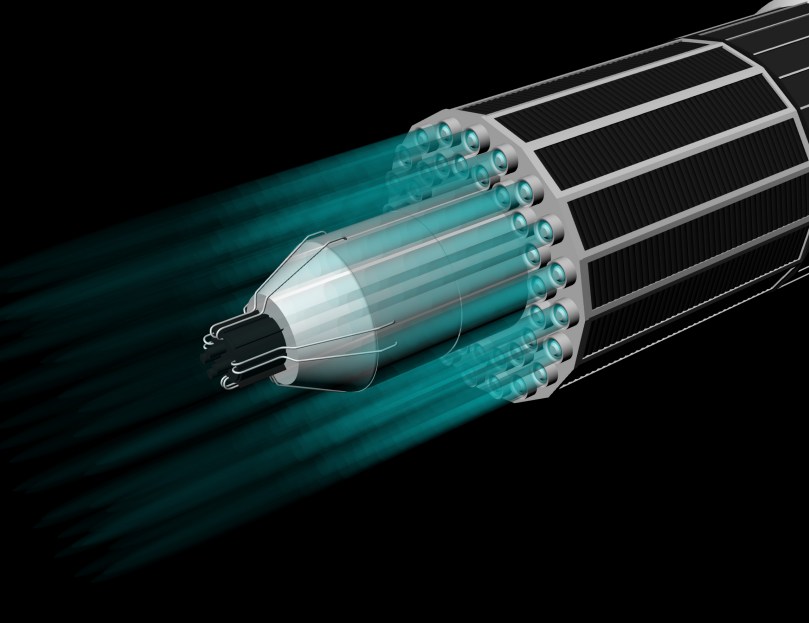

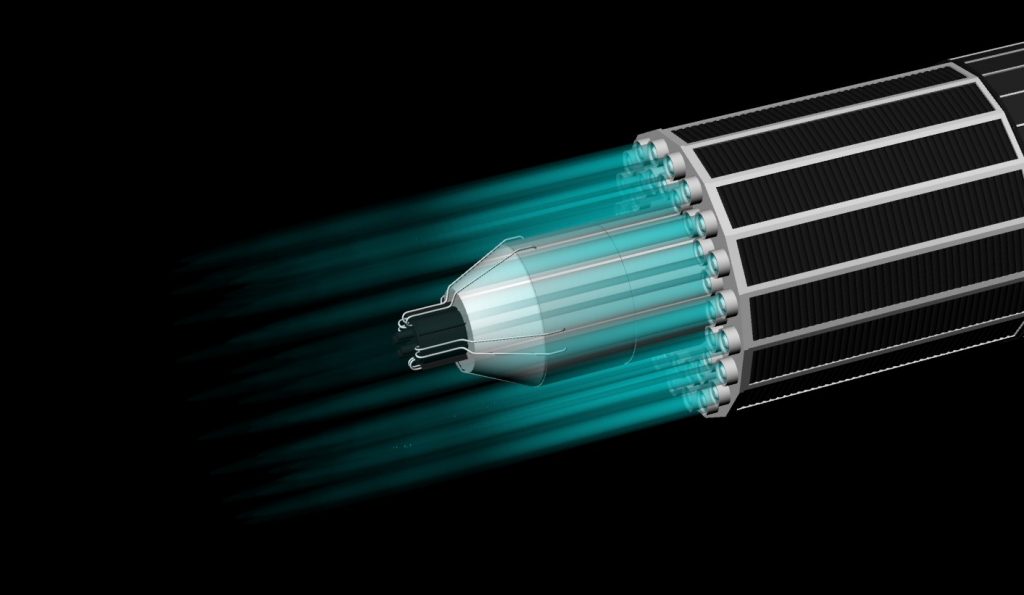

The JPL spacecraft was to be propelled by a bank of 40 ion engines. I tried to simulate that with lights in the engines, but that did some *wacky* stuff… light shining *through* solid objects, not casting shadows, all kinds of stuff that Just Ain’t Right. I don’t suppose my ancient copy of Rhinoceros 3D is really meant for that sort of thing. So I simulated the ion engine exhaust with simple transparent cylinders. Not the greatest but… does it look like it’s doing the job?

UPDATE: A better version. See comments for process.

There is an acronym that is commonly used in the various engineering disciplines (it certainly was in aerospace): TLAR.

That Looks About Right

What it means is simply that some things are so well understood and characterized that at least at first glance, to first approximation, at the back of the envelope stage, a design can look like it will work. Someone can, say, sketch out a jetliner… a tubular fuselage, modestly swept low-mounted wings, swept tail surfaces, podded engines suspended below the wings – and it will look like a “proper” design. TLAR is useful for things people have really nailed down the design of over the years. Entirely new stuff? An Alcubierre Warp Drive ring assembly, for example… who the frak knows right from wrong on that. But jetliners? Ships? Automobiles? Launch vehicles? Sure. An engineer can look at a design and say “that looks about right.”

And bridges. A good engineer can take a look at a design and say “that looks about right.” And sometimes, even an engineer from another discipline with rusty skills can take a look at a bridge design, and his engineering-spidey senses will start tingling, and “TLAR” is *not* engaged.

I look at the design of the failed FIU pedestrian bridge and man, TLAR is *not* what pops into my head. Instead I get a distinctly That Looks About Wrong feeling.

To be fair, the design of the *completed* cable-stayed bridge (by Munilla Construction Management, whose website still hilariously claims: “Safety first! At MCM Safety is paramount and we are committed to zero accidents on all projects.“) looks pretty ok to me:

It looks fine. It has two spans, each supported at the ends atop piers, and then in five places along each span by what appear to be quite stout tension cables connected to a central tower. It looks nice. Completed, it looks nice. Incomplete, it scares the pants off me:

Note how here, during the rapid assembly process, the bridge is supported from below at four points: the two ends on the piers, and within the span by temporary supports. This is a perfectly good way to install a suspension or cable stayed bridge: support it from below until you can get the cables in place. Really, there aren’t too many other practical ways to do it for a bridge like this. But where me “I want to be elsewhere and unassociated with this project” response kicks in is when they remove those central supports… without having the suspension cables in place. The design of this span just does not Look About Right for something supported only at the ends. You have a great big and seemingly massive deck at the bottom, a few centrally located diagonal supports, and then a relatively narrow structural span running along the top.

Note that the deck certainly looks pretty thin… it appears to be one, maybe two feet thick. Doubtless of steel and concrete construction, but still quite thin. As a cable-stayed span, the deck would be hanging every however many feet from those diagonal supports; the upper structure could (*could*) be virtually cosmetic. However, as a simply supported bridge, that lower deck is under a *lot* of tension, the upper structure under a *lot* of compression, and the diagonal supports transmitting those loads in a way much different from when it’s a cable-stayed span (cable stayed, they’d be in tension; incomplete, they’re in compression).

In its incomplete state, it just doesn’t *look* like a decent structure.

That’s of course easy to say now that its laying in the street. And let me be clear: an engineer should never, EVER say that something is good unless they’ve run the numbers, and should avoid saying something is bad unless they’ve run the numbers. Engineering is the wrong discipline for anyone who operates by “feelings;” it is the place for hard numbers, hard facts, objective reality. Merit rather than politics. Still: the reality is that in a world of hard facts, some things are WRONG, and you don’t need to do a whole lot of math because the facts have already been long demonstrated. You can’t run an internal combustion engine on water, nor can you tinker with your carburetor to make your otherwise unmodified Ford F-150 go 200 miles per hour and get 500 miles per gallon. You can’t make the spar of your jetliner out of butter. You can’t use a pound of dynamite to blow the Moon to flinders, nor can you make a perpetual motion machine out of a cordless drill and some weights. These are of course ridiculous examples, but there is a spectrum between “that’s obviously so stupid I don’t need to do the math” and “that looks about right.” And the FIU-Sweetwater bridge certainly falls between the two. “Feelings,” I found during my engineering days, were, when applied properly, an appropriate and useful check against unwarranted enthusiasm and optimism. I get the feeling here that someone should have been a bit more pessimistic during the design process.

UPDATE:

Well, scratch all that BS. Remember how I said that as a cable-stayed design it looked ok? Well, color me stupid:

Miami bridge that collapsed was a truss design, despite the cosmetic tower, support cables

Oy.

Whether due to a lack of rigor in the design process, the manufacturing process or the construction process… *someone* didn’t run the numbers right. And as a result, people are dead. Honestly: anyone who argues against the value and importance of engineering rigor can go eat a bag of dicks.

FIU pedestrian bridge collapses days after installation; police say multiple deaths, cars trapped

FFS, people, this sort of thing shouldn’t happen. *EVER.*

The bridge was not open to pedestrians; it appears that it was not yet even finished being built. It was, in fact, a suspension bridge… but the “suspension” part of the bridge hadn’t been built yet:

It seems that they installed the one span… and then removed the supports from underneath it, leaving it supported only at the ends:

This plan seems…unwise.

And here’s another failure of rigor, in this case either the loadmaster not doing his job, or something wrong with maintenance. Cuz doors don’t just open in flight.

Gold bars worth millions fall from plane over Russia

If you’ve ever wanted to see what a runway looks like when it had hundreds of millions of dollars worth of gold bars scattered all over it look like, that link will hook you right up. In this case, it looks like the cargo fell out as the plane rotated for takeoff. The plane was able to promptly land at another airport seven miles away. They got lucky: while the idea of gold falling out of the sky has some romantic appeal, the fact it that a bar of gold would have a *really* *high* terminal velocity as well as a lot of mass. It would do a whole lot of damage if it fell from altitude onto people or property. And if things are so bad on the plane that stuff is falling out, the chances are that the load could shift enough for this sort of thing to happen (Bagram, Afghanistan in 2013):

There’s a lot of weird in this story, but it’s an interesting read.

Poconos gunmaker’s vision: an AR-15 for every American

Short form: The son of Reverend Sun Myung Moon (you know, the Moonies) owns a firearms manufacturing company, Kahr Arms. They manufacture guns like the Thompson and the K9, and will soon be making their own AR-15 clone. That’s cool and all, but the problem with making sure that more people get themselves an AR-15 is that his AR-15 will cost $700… more than many I’ve seen. So that would hardly seem likely to make much difference. Now, if he was making a quality AR for, say $250, that would be something.

It has been fairly standard practice in the last few decades to use lethal injections to execute death row inmates. This has always been a troublesome and expensive approach, and recently difficult to carry out since the drugs used are getting hard to come by.

What has always confounded me is that there are far simpler, cheaper and more certain approaches that don;t even carry the risk of undue pain to the condemned: use inert gases like nitrogen, helium, argon, freon and the like to asphyxiate them. Unlike carbon dioxide, these gases don’t prompt the “oh crap I’m choking response.” Nitrogen, after all, makes up about 80% of every breath you take *now.* If you replace that 20% of oxygen with another 20% of nitrogen, your lungs won’t complain. They will simply continue to expel carbon dioxide from your blood; since you don;t get the choking response, you continue to breathe normally. As a result, you will also pass some perfectly fine oxygen from your blood back out through your lungs, causing you to pass out a *lot* faster than if you were in a high CO2 environment that makes you hold your breath. There have been a number of industial accidents where someone has wandered into a high nitrogen or argon or helium environment, and then quickly gone to sleep, and then quickly died.

And so, huzzah:

Oklahoma Officials Plan to Use Nitrogen for Executions

Nitrogen is cheap and omnipresent. It’s not like those whacko bizarre lethal injection drugs manufactured by only a few companies; a prison could call up Air Liquide or any of a number of other suppliers and have them bring in cylinders of compressed nitrogen or even large dewars of liquid nitrogen.

Of course, they could always think outside the box and consider alternative approaches like gigantic trebuchets, or as weight simulators on future Falcon 9 flights. Strap ol’ Dead Man Walkin’ into another Roadster and point some Go Pros at him. The footage should prove enlightening and entertaining, and perhaps even useful when played on a loop in gen pop.

A goose-stepping parrot. Because why not.

https://www.youtube.com/watch?v=BYJB0zyjt70

Don’t ask me why this YouTube video doesn’t embed like it’s supposed to. Sometimes they just don’t.

EDIT: Another YouTuber swiped the video and trimmed it a bit. This one at least embeds properly. Shrug.

Surviving many decades beyond expectation, physicist Stephen Hawking has died at the age of 76.

Well… damn.

There are people who will be remembered not just generations down the line, but centuries even millenia. I believe we’ve just seen the passing of one such. I’m not sure there are many others alive today who will be recalled as a such a scientific giant.

I’ve only been there a few times, each time on driving trips passing through along the coast. It seemed a nice enough place, except for the gas station attendants who kept freaking out whenever I started pumping my own gas. But nice as it seemed, I’m not entirely convinced that this animated promotional video for the state is 100% entirely accurate.

Oregon: The Other Wakanda

There are political and ideological lessons to be learned here. I leave it as an exercise for the student to suss out what they might be.