Sometimes the only evidence of something truly important is a photograph of heartbreakingly bad quality. Such is the case here… two photos illustrating an experiment conducted by NASA-MSFC in 1961-62.

As mentioned before, the Saturn I booster was not initially designed to be reusable, but it was designed to be recoverable. It was expected to be damaged, but inspection of the damage would allow engineers to incrementally improve the system to eventually allow for true recovery and reusability.

There was particular interest in how the rocket engines would fare after an ocean splashdown. Rocket engines are fairly fragile… easily bent and corroded. The H-1 engines on the Saturn I were also not designed to be reusable; they were designed to be inexpensive. They were derived from the Rocketdyne S-3D that powered the Jupiter and Thor IRBM… greatly simplified (around 10% the parts count, IIRC), they also had greater thrust. But they were not designed to be used more than once.

Still, this was the early 1960’s… when the 60’s were still just the late 1950’s, before a Commie blew JFK’s brains out and set the 1960’s on the road to being the “60’s.” So, what is any self-respecting 1950’s engineer supposed to do with a rocket engine designed to be used once and then thrown away? Why, test fire it, dump it into a tank full of corrosion, have the janitor swamp it out, and fire it again. So they did just that. And what did they find?

The H-1 engine was perfectly capable of being re-used, and at extremely low cost.

The two photos I have of the experiments are below. Yes, they suck. But they get across the idea magnificently. Imagine the paperwork and endless series of meetings with customers, management, Unions stewards, bean counters, environmental cops, hell, the friggen’ diversity co-ordinator that would be required to do this sort of experiment today with an engine like the SSME that actually *was* designed to be reusable.

Granted, the H-1 was not designed to be as efficient as the SSME. It did not operate at the extremely high pressure that the SSME does. A fully reusable launch vehicle based on the H-1 would be a crude affair… probably a two-stage vehicle, as getting SSTO performance would be a challenge. But still… who cares? If you can make your rocket for dirt cheap, and operate it for dirt cheap… then your pitiful payload fraction still looks damned wonderful, as your cost per pound is far less.

NASA has, over the last 45 years or so, decided that the way to make space travel cheap is by focussing on the most expensive bleeding edge technologies. Had NASA, instead, focussed not on micromanaging the technologies used in the launchers, but instead on simply *getting* *there,* then I think it’s safe to say that by now the spacelanes would be filled with tourists going to GEO hotels on the rough equivalent of VW microbuses.

A description of the tests:

H-1 ENGINE SALT WATER IMMERSION PROGRAM

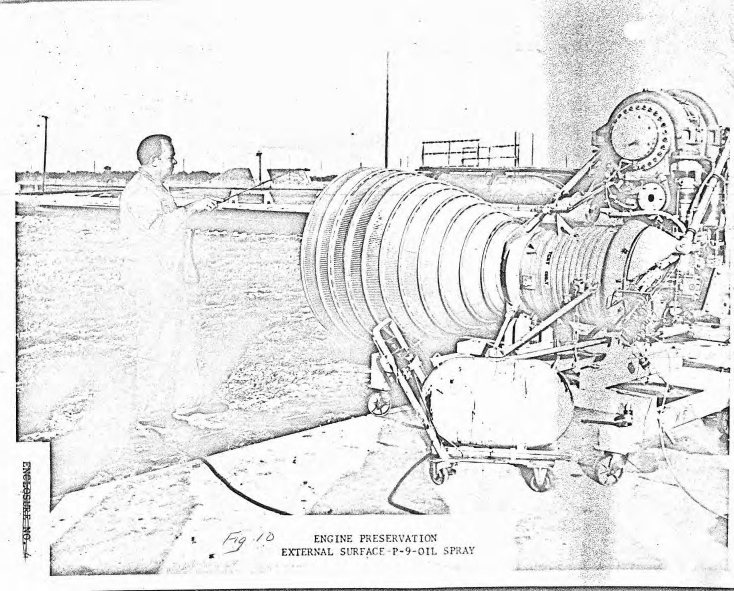

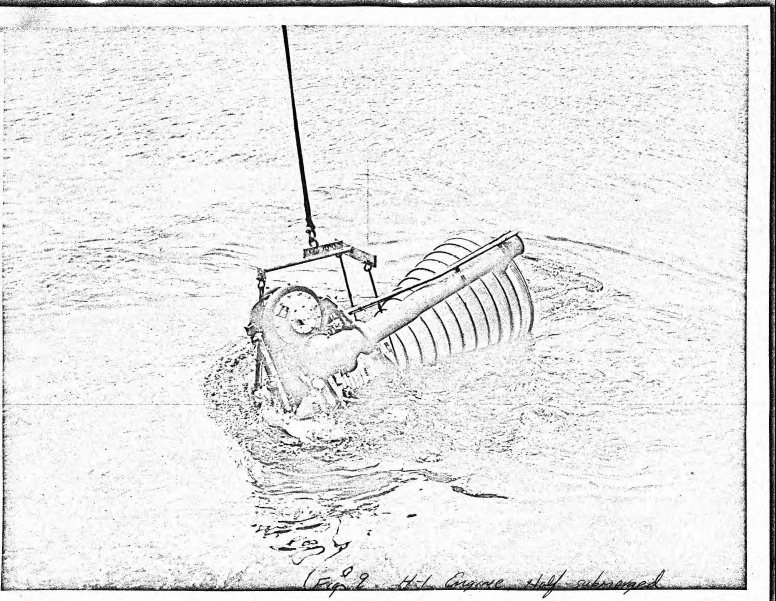

Sea water immersion tests were conducted on a Rocketdyne H-1 engine in order to evaluate the corrosive effects of sea-water recovery on the engine and to define the procedures necessary to restore the engine for flight service, The H-1 engine is the one presently used, in a cluster of eight, to power the SATURN C-1, S-I stage. The water immersion program involved a series of tests in which the H-1 engine was immersed in sea water for given periods of time, followed by various post treatments designed to minimize the corrosive effect of sea water. The engine was then disassembled, evaluated for corrosion damage, reassembled, and test fired (figures 9 and 10).Figure 9. H – 1 Engine, Half -Submerged.

Figure 10. Spraying H- 1 Engine after Recovery.

The purpose of this test program was to better define the effects of salt water immersion on the H-1 engine. Because of the various recovery schemes proposed for SATURN booster recovery, it was essential that hardware such as an H-1 engine be immersed in salt water and the results investigated to better evaluate the economics of booster recovery (wet versus dry recovery systems). The salt water immersion tests, reconditioning, and subsequent full duration static firings of the H-1 engine provided valuable information reflecting the feasibility of re-using large boosters after exposure to salt water.The test program scheduled a series of three immersion tests with subsequent hot firing in the test stand. The first test was performed with known preservative measures, the second with less preservation, and the third and final test with no preservation methods applied. The salt water immersion was performed at Port Canaveral, Florida, and the dismantling, checking of components, assembly, and hot firing at the MSFC, Huntsville, Alabama.

The general test procedures were as follows:

1. First test – March, 1961. H-1 engine was:

a. Prepared and static fired.

b. Immersed in salt water to a depth of 10 feet for 2 hours, and half -submerged for 2 hours.

c. Purged. Preservations were applied.

d. Stored for 2 weeks.

e. Dismantled, inspected, cleaned, damaged parts were replaced, and engine was assembled.

f. Hot fired for short duration and full duration (150 seconds).2. Second test – June, 1961:

a. Immersed H-1 engine to a depth of 10 feet for 1 hour, half submerged for 3 hours, and on the surface for 3 hours.

b. Waited 12 hours before purging, and applying minimum

preservatives.

c. Upon arrival at the MSFC, engine was dismantled, inspected, cleaned, damaged parts were replaced, and engine was assembled

d. Hot-fired for short duration and full duration.3. Third test immersion in August, 1961; hot fired in March, 1962.

a. Dropped H-1 engine into water to simulate water entry conditions, immersed it, held it half-submerged, and on the surface for a total of 9 hours.

b, Engine washed with fresh water; – no preservative compounds were used.

c. Upop arrival at the MSFC, engine was dismantled, inspected, partially cleaned, ind left in storage.

d. Six months later the engine was assembled and hot-fired for short duration and full duration.In order to establish an approximate cost factor, a log was kept of the procedures, reconditioning manhours, materials, and an itemized list of replaced engine parts. The cost to recover and recondition the H- 1 engine was approximately 5 per cent of the cost of a new one.

12 Responses to “H-1 reusability: Bad photos of lost awesome”

Sorry, the comment form is closed at this time.

Although you could clean them up after a dunk in the ocean, it would have made a lot more sense to have the stage float with the engine bells upwards, like the recoverable version of the Saturn V first stage was designed to do.

You probably could have perforated the central LOX tank and four of the eight peripheral tanks and let them flood on landing to get it float in the correct orientation.

Another problem would be if it hit the ocean engine-bells-first, as the impact could have distorted the nozzles; or was this for the version that was supposed to descend horizontally under the big Rogallo parawing?

You would also have to check the cost trade-off of reduced first stage performance by putting the landing rockets and parachutes on it, versus the money saved in re-using the engines; since each Saturn I used eight of the engines, there was obviously going to be a good-sized production line for them if Saturn I saw long-term use, and that could cut the per-engine cost down.

>hthave the stage float with the engine bells upwards

The S-1 stage was ass-end-heavy, and not much could be done to change that.

Did it id the definitive Karma of NASA, validating a lot of good ideas, getting them for real, and after….simply wasted and replaced with something different and far complex that probably won’t work.

And after that all over again…and again…and again…

I never liked the Saturn I family, but in retrospect, it probably should have stayed in production like the Russian R-7 family. Imagine how cheap it would be on a per-unit basis by now.

The first stage was sort of heavy due to the technique of surrounding a central LOX tank built with Jupiter tankage assembly equipment with eight tanks (four LOX/four kerosene) built using built using Redstone tankage assembly equipment, so it was bigger than it needed to be for its propellant volume.

The Army wanted a big booster in a hurry and at low cost for its Project Horizon lunar base concept: http://www.astronautix.com/articles/prorizon.htm

…and von Braun’s team whipped up Saturn I in a hurry to meet that need, using off-the-shelf technology whenever they could, even if it wasn’t the optimal way of doing things from a performance viewpoint. With the cancellation of Horizon, that left only the Apollo orbital tests for the Saturn I, so it didn’t really have a planned mission beyond Apollo.

It was floated as a possible booster for the Air Force’s X-20 Dyna-Soar space plane or a launcher for a space station module, but the Air Force developed the Titan III for those missions, and it was a lot smaller and easier to move around than the Saturn…which would have needed a new pad at Vandenberg for military use.

So Saturn V was pushed out of the launcher picture by Titan III, the same way the Jupiter-based Juno II was pushed out of the picture by the Thor variants that evolved into Delta.

From the aesthetic viewpoint though it was really very attractive, particularly with the eight tail fins of the Saturn IB.

I know the first stage was far from an optimal design, but neither is the Soyuz launcher, and yet it keeps going and going…

The Saturn I had a cryogenic upper stage and there were proposals to add large solids. If you were just looking for a reliable rocket with high-medium payload capability, it would have done the job. But the AF never would have used an Army rocket. That was probably the biggest impediment. Saturn IB could have easily flown a MOL.

Just as an observation Scott but when you wrote:

“NASA has, over the last 45 years or so, decided that the way to make space travel cheap is by focussing on the most expensive bleeding edge technologies. Had NASA, instead, focussed not on micromanaging the technologies used in the launchers, but instead on simply *getting* *there,* then I think it’s safe to say that by now the spacelanes would be filled with tourists going to GEO hotels on the rough equivalent of VW microbuses.”

While it’s a nice IDEA I’m thinking politically it would never fly. Congress tends to, (hell admit it they go out of their way it seems) to demand funding only “bleeding-edge” technology during NASA (or for that matter DoD and just about anyone else they get a ‘say’ in ) programs and they de-fund or cancel programs that use “older” technology.

(And again, granting that they tend to cancel ANY and ALL projects before anything can actully be produced seems to be a way of life for Congress-critters)

On the commercial side of the argument though you have the costs associated with a “reusable” anything for low-flight-rate type government missions and the distinct lack of market (also leading to low-flight-rate/high-cost operations) for commercial payload lift.

I’d LOVE to see a move for pulling a good solid (not rocket, structure :o) booster design together from older technology and “off-the-shelf” parts but my question remains: Can you actually close a business case given the relativly narrow market for such?

Randy

Question for whomever:

If the Saturn-1Bs were for the Apollo flight tests were the Skylab launchers “left-overs”?

Randy

Soyuz booster is a real kludge of a thing, using engines that are one step forward from those used on the V-2 as far as technology goes.

The engines managed to use: Liquid Oxygen, Kerosene, Hydrogen Peroxide, a catalyst for the Hydrogen Peroxide (Calcium Permanganate? Silver?), Nitric Acid, Hydrazine, and Nitrogen Gas (or maybe even

Liquid Nitrogen) during their operation.

About the only upside of the thing was that you could jettison the propellant tankage on the four strap-on boosters as well as the engines, unlike Atlas.

As far as Skylab went, they used Saturn IB’s that were already in the production pipeline at the end of the Apollo orbital flights.

In its “wetlab” incarnation, a space station using the S-IVB stage went pretty far back, and was one of the original ideas in the Apollo Applications Program that was going to follow Apollo proper.

The strange one was the Saturn IB booster used for Apollo-Soyuz, which was partially built from leftover parts and had fin numbers that didn’t line up right.

It was originally intended to launch a rescue Apollo CSM to Skylab if one of the crews got stranded in orbit, like in the movie “Marooned”, but after the end of Skylab it had been allowed to deteriorate.

[…] a followup to the H-1 saltwater immersion test posting, here is an actual decent-quality photo from the […]

Randy:

Sometimes old technology is not simple. The H-1 has a gear drive that more modern LOX-Kerosene engines don’t have.

Sometimes being a little cleverer allows you to do things in a much simpler way. Pump design has advanced since the fifties. I don’t think replicating a H-1 would make sense.

> I don’t think replicating a H-1 would make sense.

One could do with the H-1 what was done with the S-3D before it. Tear the design apart, and rebuild it using better designs and materials here and there… so long as the goal of lower cost/lower parts count remains. But far too often the goal is not lower cost, but higher performance and *only* higher performance.